When Quality decides what matters most

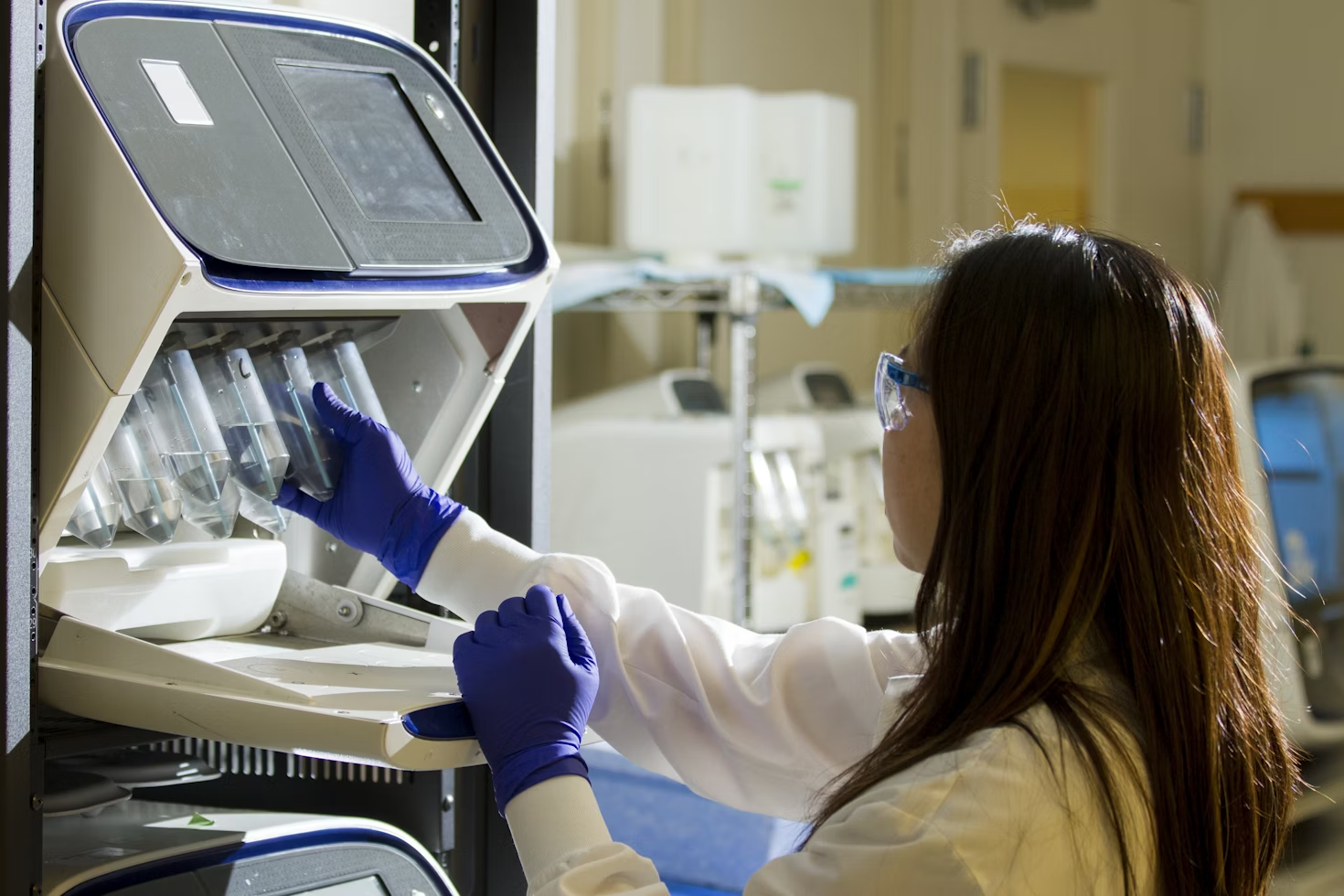

Testing equipment in the pharmaceutical industry ensures product quality, regulatory compliance, and adherence to good manufacturing practices (GMP). It minimizes risks, enhances efficiency, and guarantees reliable results throughout production.

Scientific equipment serves as the backbone of the pharmaceutical industry, driving innovation, ensuring precision, and maintaining quality across every stage of drug development and production. From research laboratories to large-scale manufacturing units, these tools are indispensable in creating safe and effective medicines.

Key focus

Quality Control and Assurance In the pharmaceutical industry, the stakes for quality are incredibly high. Equipment like high-performance liquid chromatography (HPLC) systems, mass spectrometers, and dissolution testers ensure that drugs meet stringent quality standards. These instruments allow professionals to verify composition, purity, and shelf stability with utmost accuracy.

Research and Development (R&D) Scientific equipment such as spectrometers, chromatographs, and microscopes are crucial in the R&D phase. They help researchers analyze the molecular structure of compounds, test chemical interactions, and understand biological processes. Advanced tools like nuclear magnetic resonance (NMR) machines enable the precise identification of chemical properties, paving the way for breakthrough discoveries.

Manufacturing Production

During the production phase, scientific equipment plays a vital role in scaling up processes and ensuring consistency. Bioreactors, mixers, and automated filling machines are examples of equipment used to produce pharmaceuticals at scale while adhering to regulatory guidelines. Real-time monitoring tools enable manufacturers to optimize efficiency and minimize risks.

Particle Size Analyzers

Instruments like laser diffraction analyzers help measure and control the size of particles in formulations.

The EP-1 is the ideal desktop tablet press for R&D purposes. The single punch eccentric Tablet Press EP-1 can manufacture tablets and odd shaped products with a diameter of up to 20 mm. It operates automatically i.e. the die is filled with powder or granule, the material compressed, and the tablet ejected continuously. The compression force of up to 3 tons and the filling depth of up to 17 mm are easy to adjust.

Clinical Trials and Validation Sophisticated instruments are employed to gather data during clinical trials and validate results. Tools like electronic lab notebooks (ELNs) and sample analyzers facilitate efficient data collection, analysis, and documentation, ensuring compliance with regulatory bodies.

Spectroscopy Instruments

Fourier Transform Infrared (FTIR) Spectrometer: Used for analyzing the chemical composition of samples.

UV-Vis Spectrophotometer:

Helps in determining the concentration of substances in solutions.

Chromatography Equipment

High-Performance Liquid Chromatography (HPLC) System: Vital for separating, identifying, and quantifying components in a mixture.

Gas Chromatograph (GC): Primarily used for analyzing volatile compounds.

Microscopes

Electron Microscope: Allows detailed imaging at the molecular level.

Fluorescence Microscope: Commonly used in drug discovery to observe labeled samples.

Mass Spectrometry Instruments

Liquid Chromatography-Mass Spectrometry (LC-MS): Combines chromatography with mass analysis for precise identification.

Matrix-Assisted Laser Desorption/Ionization Time-of-Flight (MALDI-TOF) Spectrometer: Useful in protein characterization.

Bioreactors

Stirred-Tank Bioreactors: Used in cultivating microorganisms or cells for biopharmaceutical production.

Wave Bioreactors: A disposable and efficient solution for growing biological cultures.

Dissolution Testers

Tools for studying the rate at which a drug dissolves in specific solutions, critical for oral dosage forms.

Links

Products

Contact Info

Phone

+971 559 64 74 84

sales@equipmentor.ae

Address

No.9, M7, Musaffah Abu Dhabi UAE